Services

Design & Engineering

Our in-house Design and Engineering Department supports clients from concept to construction, providing fully detailed and coordinated façade design solutions.

We specialise in the design and engineering of natural stone finishes, as well as precast cladding systems faced with stone, brick, terracotta or other architectural materials. Our scope includes both traditional and contemporary schemes and we work closely with architects, contractors and developers to deliver technically robust and visually considered solutions.

Our structural engineers provide complete structural design packages with calculations suitable for building control approval. We also carry out detailed thermal bridging assessments, movement and tolerance analysis and fixings design.

Using industry-standard software such as AutoCAD, Tekla, and Revit, we produce coordinated 2D and 3D design models, fabrication-level drawings and BIM outputs. All our designs are fully compliant with applicable codes, including Eurocodes, CWCT guidance and have the flexibility to achieve project-specific requirements.

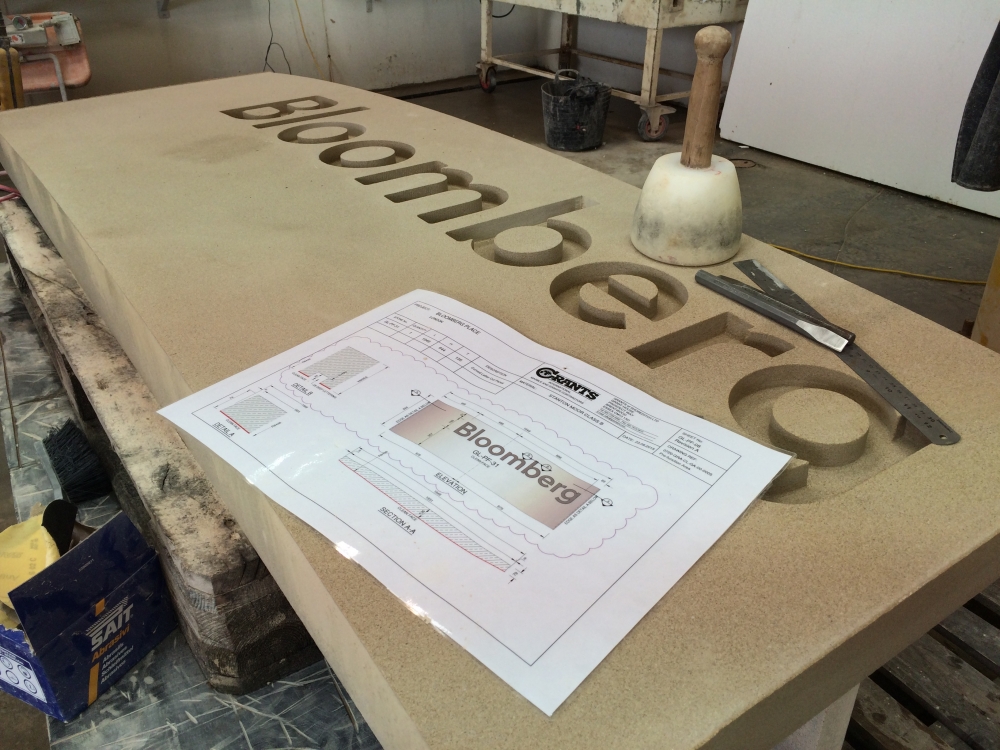

Manufacture

Our integrated manufacturing facility in Cadeby, Yorkshire combines natural stone and precast production on a single site—one of the only such facilities in the UK.

This co-location allows us to reduce our carbon footprint, streamline coordination, maintain exceptional quality standards and deliver any project with flexibility and control.

We produce a full range of natural stone and architectural precast elements, including stone-faced precast cladding. Our stone fabrication benefits from the use of CNC machinery to achieve consistent precision finishing, while our precast operations are deliberately craft-led, allowing us to take on complex, high-detail architectural work that cannot be automated.

With nine of our own quarries across the UK and a long-established international supply chain, we can source and supply natural stone as quarry block, slab or finished product, tailored to suit the project’s needs—any material, to any destination. Our workforce includes highly skilled stonemasons, qualified joiners and specialist precast fabricators.

All manufacturing is supported by thorough Quality Assurance or Quality Control processes including dimensional checks, inspection records, dry builds and full mock-ups.

We manage packing, crating and delivery in-house, with dedicated storage capacity to support just-in-time and sequenced site deliveries, helping to ensure programme certainty and protection of finished goods from factory to site.

Installation

We offer a fully managed construction service, combining skilled craftsmanship, precise coordination and robust quality assurance from start to finish.

As a specialist subcontractor, we carry out installation using a combination of our in-house qualified stonemasons, lifting operations specialists and a carefully selected supply chain. Our team’s vast experience working for tier 1 contractors on large, blue-chip projects ensure Health and Safety standards are to the highest level, co-ordination with other trades is achieved and that we have a ‘get it right, first time’ approach.

We maintain comprehensive Quality Assurance procedures and site-based record keeping throughout the installation phase, ensuring full traceability and alignment with project and compliance requirements.

Our operatives are trained in logistics and lifting operations including appointed persons, slingers and Temporary Works Coordinators. We also maintain a range of specialist lifting equipment to safely handle complex façade elements.

Façades are installed by experienced masons with an eye for detail, ensuring that architectural vision is delivered with precision and care on site.

Stone Selection & Supply

Correct Stone selection is vital to the success of any stone project. Decisions regarding the selection of a stone involve many factors including the following:

- The architect’s aesthetic requirements (Colour, texture etc)

- Physical properties and durability requirements of the stone.

- Capacity of the Quarry and its production capacity.

- Seasonal quarrying period.

- Location of the Building (Climatic conditions.)

- Rough block sizes available, nominal bed heights.

- Cost of Block.

- Commitments of the quarry to other clients.

- Colour and general visual variation of the stone.

- Detailing of the Stonework.

The yield of a quarry can change very quickly so an evaluation of a quarry should be undertaken regularly. Our experienced Geologist based in Carrara, Italy, undertakes quarry evaluations and surveys throughout the world.

Consultancy

Our consultancy service offers strategic guidance across all stages of a project, with the greatest value realised when we’re engaged early, often from RIBA Stage 2 or even pre-planning.

We support architects, contractors, developers and clients with both technical and practical advice on material selection, feasibility, buildability and early-stage construction strategy. This early involvement helps shape coordinated, efficient solutions that align with design intent, technical requirements and delivery constraints.

Our input covers a wide scope, including façade strategy (e.g. precast, handset or hybrid approaches), material and range selection, logistics planning, mock-up and testing strategies, programme coordination and value engineering. Backed by real-world experience in quarrying, manufacturing and installation, we bring a grounded, delivery-focused perspective that enhances both the design process and its practical execution.

Consultancy is typically delivered through active participation in workshops, design reviews and coordination meetings, ensuring advice is timely, informed and fully integrated into the project journey.